Friendly

Our promise

to the future

Our friendly philosophy

is more than just superficial sustainability banter. For us, sustainability is not a trend, but a promise. An honest promise to fulfil our self-imposed responsibility - across all areas of the company. This begins with the considerate use of resources, extends to fair and bicycle-friendly working conditions for our employees and culminates in a circular economy in which we obtain 100% of our energy from hydropower and reuse waste heat for our production halls.

Why are we doing this?

Because we as a company do not want to be part of the problem, but part of the solution. Because we want to help save energy, conserve resources and generate less electronic waste. And because we want to protect our employees

Customer and environmentally friendly: our products

Cycling is healthy, environmentally friendly and relieves cities of car traffic - more than enough reasons to get on your bike regularly. Our lighting solutions ensure that you are visibly better on the road - especially at dusk and in the dark. As a contribution to the desired traffic turnaround, we are therefore working hard every day to inspire you sustainably. With products that not only fulfil their purpose - but are also a strong and reliable companion for years to come.

IQ-XS friendly made from compostable plastic

Are you already familiar with our high-quality and durable IQ-XS friendly headlamp, for example? It is the first headlight in the world to have a compostable, 100% biodegradable plastic housing. The special material contains no fossil raw materials and leaves no microplastics behind, even if disposed of improperly.

Packaging and packaging materials

But we think even further!

It's not just our products that are sustainable. We also consistently ensure that our packaging is made from environmentally friendly materials and can be recycled.

- We have switched our product packaging from blister packs to cardboard.

- We use FSC-certified cardboard for all our cartons. The wood for this comes exclusively from sustainable forestry.

- We have also switched to FSC-certified cardboard for our outer packaging boxes.

- Our filling material (chips) is biodegradable.

- Adhesive strips are made of environmentally friendly material.

- Internally, in production and the warehouse, we use durable transport boxes without exception.

We are also working on solutions to reduce the use of small plastic bags and - wherever possible - to use other materials instead of plastic.

Help us make the world a better place!

We can make sustainable products and produce in an environmentally friendly way. But when it comes to disposing of our products and packaging, we need your support!

Help us by

Always dispose of products and packaging in accordance with the laws and regulations applicable in your municipality.

Dispose of all products containing electronic components (i.e. all headlights and tail lights) in the electronic waste.

Don't throw away old, still-functioning products, but give them a second life by handing them over to a social department stores' or second-hand shop.

Open, inclusive and friendly: our work culture

Busch + Müller actively promotes a work culture in which a wide variety of people with diverse life stories work together successfully. For us, employees are not a resource: it is important to us that the people who support us in our mission are satisfied, motivated and healthy.

That is why we take the wishes and needs of our employees seriously and enable them to work in a way that they feel comfortable with. This starts with occupational health and safety and extends to many other aspects of working together:

Occupational health and safety and working conditions

As a company that produces exclusively in Germany, we ensure that all our employees work under the high standards of occupational health and safety as well as under healthy and environmentally friendly conditions.

Bicycle friendliness

As a manufacturer of products for bicycles and e-bikes, we are of course also bicycle-friendly. That's why Busch + Müller has a storage room for bicycles including charging facilities for e-bikes. We also offer the option of a company bike. This allows our employees to save money, protect the environment and do something good for their health.

Home office and working from home

In order to save travelling time and therefore CO2, we enable our employees to work from home whenever possible. At the same time, we are responding to the widespread desire for a better work-life balance.

Sounds good to you?

Then become part of the teamRegional and responsible - from production to administration

At busch+müller, Made in Germany means: Made in Meinerzhagen. Because we do everything - and by that we really mean everything - at our site in the Sauerland: from research, development, lighting and product design to production, final assembly, marketing and sales, right through to storage, dispatch, service and administration. With comprehensive vertical integration, we not only manufacture our own circuit boards, but also build our own tools.

This has several advantages:

- We can guarantee the optimum quality of our products throughout the entire manufacturing process.

- We save a lot of CO2 thanks to short or completely eliminated transport routes.

- We retain direct control over the sustainability of our processes.

Find out more about how we live "Made in Germany" in Meinerzhagen: Learn more

Use of green electricity

Since 2023, we at busch+müller have been sourcing all of our electricity from hydropower. This enables us to save more than 850 tonnes of CO2 every year while promoting the expansion of renewable energies.

Waste management

Our entire busch+müller team is aware of the importance of conserving resources in terms of materials and consumption. We minimise waste and separate it carefully.

Natural air conditioning

For cooling, we rely on a simple ventilation system that uses natural air flow. We don't use energy-intensive air conditioning in either our production or administrative facilities.

Supporting the natural groundwater cycle

With the help of an infiltration system, we feed around 60% of the precipitation on the sealed company building directly into the natural groundwater cycle. This reduces the load on the municipal sewage treatment plant and the public sewer system.

LED lighting in our new building

The new part of our building has full LED lighting, which is controlled by a system of motion detectors and timers to save energy. All light bulbs in the old building have also been replaced with LEDs.

Sustainable insulation in our new building

Our company building, constructed in 2016, was built according to the latest standards in construction technology and thermal insulation. Only recyclable, high-quality materials were used to ensure the longest possible service life.

Our old building was also completely renovated in 2020 using sustainable and durable materials to improve its energy efficiency.

Utilisation of heat loss

To melt the plastic granulate, our injection moulding machines convert electrical energy into heat. We use the resulting lost heat to heat our premises, saving around 25% in primary energy each year.

Use of biological oil

We use sustainable biological oil as the hydraulic medium in our lift system.

Used oil reduction thanks to oil filters

We continuously check the hydraulic oil used in the injection moulding machines for contaminants. If there are any deviations, we filter the oil and can then reuse it. As a result, we produce very low levels of used oil.

Sustainable galvanisation

We operate our own galvanising plant at our site and produce this form of surface coating in accordance with European and German specifications. This ensures that our galvanising process always complies with the latest standards in terms of technology, occupational safety and environmental compatibility. We treat the wastewater from the galvanising process in a modern ion exchange plant, enabling us to discharge it safely into the sewage system.

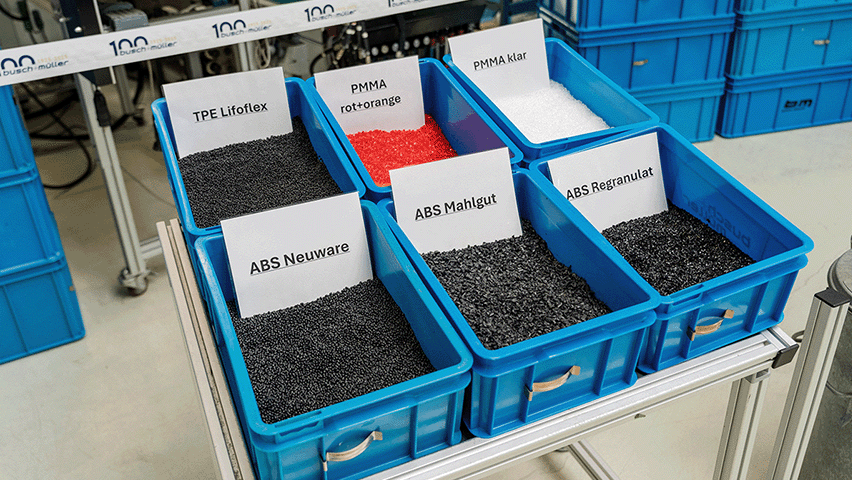

Circular economy in plastic injection moulding

Plastic injection moulding always produces a certain amount of waste during production. We grind these plastic parts into granulate and return them to the production process.

Checked, tested, confirmed: Our awards and certificates

Our products and processes meet the highest standards of quality and sustainability.

Anyone can claim that, of course. That's why we prove it - with corresponding certificates and awards. As a customer, you can quickly and easily see for yourself that we at Busch + Müller actually keep our promises. And it serves as an incentive for us to not only maintain our standards, but to constantly improve them.

Our awards and certifications at a glance:

DIN EN ISO 9001

We have been fulfilling the DIN EN ISO 9001 standard for quality management since 1997. This is official proof of the effectiveness of our processes in terms of improving customer satisfaction, optimising processes within the company, increasing efficiency and reducing costs, as well as the systematic handling of company knowledge.

DIN EN ISO 14001

All Busch + Müller products as well as all company processes fulfil at least the requirements of the EN ISO 14001 standard, which is checked (audited) and officially certified annually by an independent testing institute. In addition, Busch + Müller has installed an environmental management system that goes far beyond the requirements of the standard, whereby the control of sustainability is also extended to suppliers.

GREEN AWARD

In 2009, Busch + Müller was honoured with the Eurobike Green Award for the E-WERK. This award recognises special products and ideas that take sustainability and environmental protection to a new level in the bicycle market. The jury's statement: "The E-WERK is an appealing idea - generating electricity while riding. This makes you completely independent of the power grid, even in remote areas." By 2025, only eight Green Awards had been presented by the critical jury!

VSF product certification

In 2021 we were certified by the VSF. Verbund Service und Fahrrad (VSF) is an independent trade association for the bicycle industry that represents more than 300 dealers, manufacturers and service providers. It stands for high quality standards, sustainability, fairness and reliability. The VSF has installed a system that involves experts from various fields with many years of professional background in the analysis. The result is reliable product recommendations and high-performance items with maximum functionality and durability, ideally manufactured in a particularly sustainable way and under fair social conditions.

For the environment, people and the future: our commitment

We believe that sustainability should not be reactive, but proactive. That is why we have been involved in various technical and social areas for many years - for a better future.

"Aktion Mensch"

busch+müller has been supporting "Aktion Mensch" since 2011. The organisation supports projects that help to improve the living conditions of people with disabilities, children and young people.

Social institutions in the region

We support numerous regional organisations that are involved in a wide range of areas - from environmental protection, sport and schools to social and church projects.